Cardboard boxes guide

Cardboard boxes guide

How to measure a cardboard box

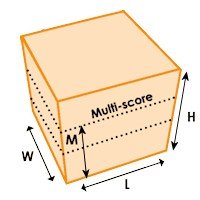

The measurements of a cardboard box always refer to the internal dimensions of the carton (the usable space), not the external dimensions. Depending on the grade and fluting of the cardboard, the internal and external dimensions of a box can differ significantly.

The first dimension is always the longest opening dimension. The second dimension is the shortest opening dimension. The third dimension is the height (sometimes referred to as the "depth").

Remember to leave space for any extra padding you wish to use to protect your product. For example, if you are using bubble wrap to cushion the item then you should add at least 5mm to each dimension.

Different types & grades of corrugated cardboard

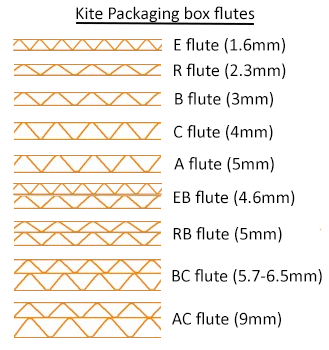

Corrugated cardboard consists of a corrugated sheet (the "fluting") that is glued to a flat sheet of paper (the "liner").

Cardboard boxes are made from corrugated board that has a liner on both the inside and outside of the fluting. The strength depends on the combination of the size of the fluting and weight of the paper.

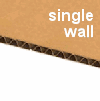

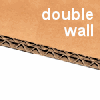

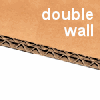

A single sheet of fluting that is sandwiched between two sheets of paper is referred to as single wall cardboard. By adding a second sheet of fluting you get double wall cardboard which offers extra strength (suitable for heavier items, more resistant to crushing when stacked, better puncture resistance).

You can get cardboard in a variety of sizes of fluting, and each has its own benefits. Smaller the fluting means the cardboard will have more rigidity, whereas larger fluting offers better cushioning to your goods. Double wall cardboard is commonly made from 2 different sizes of fluting, so you get the benefits of both types.

If the fluting only has a liner on one side (leaving the other side as bare cardboard fluting) then it is referred to as single face board. It does not have the same strength or durability as other types of cardboard, but it is cheap to produce and is commonly used for padding and protection.

Cardboard boxes can be made from two different types of paper. Kraft paper is manufactured from softwood trees. Thanks to these "virgin" fibres it is both strong and easy to print on. This means it is commonly used for the outside liner paper of cardboard boxes. Test paper is made using recycled paper. This means it is cheaper to manufacture but it gives the paper a mottled effect. It is commonly used to for the inner liner of cardboard boxes.

What is a multiscore box

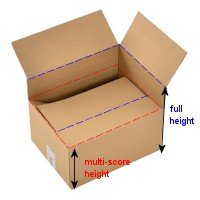

Many of our boxes have a multiscore feature, giving you the option to vary the depth of the box to a pre-scored dimension. As well as functioning like a standard cardboard box, they also have an extra crease on the inside of the box.

Simply cut the existing slots (between the flaps), fold along the pre-scored crease, and you create a shallower depth carton.

The diagram to the right illustrates a multiscore box. The blue dashed line is the full height of the box, where as the red dashed line is multiscore height. In this diagram we have already cut down between the two front flaps and folded the front side of the box to the new reduced height.

Some boxes have more than one multiscore depth, offering you a wide variety of box heights whilst only having to keep a single size of box in your warehouse.

Which type of box do I need: compare our most popular types of boxes in the table below:

| Type |

Standard single wall |

Heavy duty Enviro-box |

Heavy duty double wall |

Extra heavy duty double wall |

|

|---|---|---|---|---|---|

Click to view |

Click to view |

Click to view |

Click to view |

||

| Specifications | |||||

| Board thickness |

|

|

|

|

|

| Strength guide |

|

|

|

|

|

| Other features | Our best value boxes | Environmentally friendly alternative to double wall | Suitable for most uses | Strong alternative to triple wall | |

| Suitable For | |||||

|

Lightweight storage (eg. toys) |

|||||

|

Fragile items (eg. porcelain) |

|||||

|

Heavy items (eg. books) |

|||||

|

Very heavy items (eg. engineering parts) |

|||||

Compare single wall, double wall and Enviro Boxes and discover which is best for your product

We sell various types of boxes, from standard duty single wall to extra heavy duty.

Single wall boxes are identified by the prefix ‘CSW’.

Heavy duty Enviro-boxes have a clear ‘Enviro’ print on one of the flaps.

Double wall boxes have a code starting ‘CDW’.

Our single wall boxes have a single layer of corrugated board. They are our best value option for packing lightweight goods. Enviro-boxes are made from a thicker and more rigid single wall board. These are suitable for slightly heavier goods. Double wall boxes have 2 layers of corrugated board, making them our strongest general-use boxes.

A demonstration on how to measure your product correctly, and choose the right box.

Step 1:

How big is your product? Standard box dimensions are given in the order Length x Width x Height. Measure the length with a tape measure. Next, measure the width. Measure the height / depth.

Step 2:

Select a box that is slightly larger in all 3 dimensions. This will allow for extra padding to protect your product. You will need the INTERNAL dimensions of the box. Depending on the board grade, this could be up to 10mm less than the external dimensions. To check that your box is the correct size, measure the length, width and height on the INSIDE of the box. All dimensions provided for our boxes are internal.

Step 3:

Wrap your product in a suitable padding material and place inside the box. It should be a snug fit to prevent movement.

Step 4:

Close the box and seal with tape or strapping as required Consider our custom logo printed tape for a cheap branded sealing option.