Loading products

Strapping machines

Strapping packages for transit or storage using a hand operated tool is no problem for businesses dealing with a small number of items each day. Those with a higher volume to strap, however, should invest in one of our strapping machines for maximum efficiency.

We stock two types of strapping machine: semi-automatic or fully automatic.

- Semi-automatic: these machines are fast and reliable, suitable for small and medium sized items and requires its user to manually feed strapping into it.

- Automatic: these machines are suitable for larger and wider packages, and do not require the user to manually feed strap. Requires very little maintenance.

All models come with a 12 month warranty (national service team).

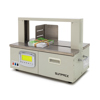

Semi-automatic strapping machine

When you encounter an increase in the number of parcels you are strapping on a daily basis in preparation for storage or despatch, it may be time to consider a semi-automatic strapping machine as a cost-effective, time-saving device. Ideal for everyday use with fairly uniformly sized parcels, this easy to use strapping machine will automatically tension and seal the polypropylene strapping around your goods for a professional finish every time.

This system will help you improve the efficiency of your operation by providing fast, consistent and reliable strapping through semi-automated operation. Simply feed the strapping into the machine manually while it does the rest, proving to be easy to operate as well as requiring very little maintenance. Its settings can be adjusted to extend seal time (by up to ½ second) to seal heavier grade strap or springy packs.

Offering a lighter, quieter and greener means for strapping your goods when compared to its predecessors, this system will help you to operate with greater environmental responsibility. It’s great for those that require a flexible option thanks to its swivel castors which allow operators to move the system to wherever they need.

| Technical details | |

|---|---|

| Strap width: | 5, 6, 9, 12 (15.5) mm |

| Strap thickness: | 0.55 - 0.7 mm |

| Adjustable height: | 750mm |

| Max strapping tension | 5-40kg |

| Max loading weight | 180kg |

| Strapping type: | Polypropylene |

| Dimensions (WxDxH): | 785 x 545 x 750mm |

| Weight: | 65kg |

| Min package Size: | 100mm width x 30mm height |

| Power supply: | 220V 50HZ 1Phase 110V 60HZ 1Phase |

Paper or film semi automatic strapping machine

This is a high speed, versatile tabletop strapping system which can be used to apply paper and film tape to your goods - click here to view our range.

It offers a high speed solution for those securing large volumes of goods on a daily basis, operating at up to 25 cycles per minute without sacrificing any speed regardless of whether soft or elastic bundles are being created.

Versatile in the size of packages it can band, this system impeccably seals your goods, eliminating curling, folding or peeling of tape edges. It’s is very simple to use, operated with a push button to begin strapping and a pause mode to eliminate any potential tearing.

This machine comes with a 12 month warranty.

| Technical details | |

|---|---|

| Arch size | W 460 x H 200mm |

| Width | 611mm |

| Depth | 364mm |

| Height | 475mm |

| Weight | 32kg |

| Table height | 240mm |

| Minimum package size | W 30 x H 10mm |

| Maximum package size | W 460 x H 180mm |

| Paper strapping | W 30mm x 150m 80g |

| Film strapping | W 30mm x 150m 120 micron |

| Strap tension | 5-40N adjustable |

| Power supply | 220V 50hz 1phase or 110V 60hz 1phase |

Automatic strapping machine

Automatic strapping machines are an invaluable time-saving addition to any high volume packing and strapping operation. Favoured by successful businesses where both output speed and labour costs are a key consideration, automatic strapping is now an affordable investment that can be integrated into a packing production line if required.

Our professional strapping machine uses polypropylene strapping to create uniform parcels, helping to increase the overall presentation of your goods.

Choose our automatic strapping machine for large and wide packages and benefit from an array of features.

This

high speed system is easy to use and secures up to 37 straps per minute,

offering quick and efficient strapping for businesses dealing with large

volumes of goods on a daily basis.

It benefits from a space-saving design featuring a coil

holder within its body frame to enable easy incorporation into your existing

set up. Its portable design includes locking castors which allow operators to

move the machine to wherever goods are being strapped, providing additional

safety when locked.

There’s no need to manually feed strapping into this machine,

simply insert the tip of a strap into the machine to load and the system is

ready to start strapping. An error lamp will indicate when the coil is empty while

an auto shut off feature turns the machine off after 30 seconds of idling.

In the event of strap feed failure, the machine is

programmed to reset and re-feed strapping to ensure smooth operation. If the

machine is operated with no package in place, an unsealed strap loop is cut and

ejected from the machine. An advanced reel brake system ensure smooth breaking

of the strap steel without the use of wear parts.

This machine comes with a 12 month warranty.

| Technical details | |

|---|---|

| Arch size | W 650 x H 400mm |

| Strap width: | 9 and 12 mm |

| Dimensions (WxDxH): | 921 x 600 x 1336mm |

| Table height: | 827mm |

| Minimum package size | W 60 x H 30 mm |

| Maximum package size | W 620 x H 380 mm |

| Weight: | 115kg |

| Speed: | 1.7 secs / strap, 35 straps per minute |

| Strapping type: | Polypropylene |

| Power supply: | Power Supply 230/240 volts standard |

High speed automatic strapping machine

A market-leading strapping machine offering a higher strapping speed, with an integrated foot bar, height adjustment and a built-in cycle counter.

This high-speed, automatic strapper can secure up to a 55 packages a minute. It offers many advantages including energy efficiency, ease of use, auto re-feeding and jam resistance. A dedicated tension motor reduces wear on parts (e.g., interlock shaft, tension, pulley) and improve speed. The built in cycle counter makes it easy for users to keep track of strap cycles and plan maintenance schedules, ensuring longevity.

The machine features self-correcting technology which ejects small loops of strapping from the sealing unit if it is used without a package on the table. The machine then re-feeds ready for the next cycle.

Strap loading is as easy as a touch of a lever as there is no need to thread the strap to begin operating. If any feeding issues occur, the machine will re-feed the strap automatically to ensure the smoothest possible operation.

It is easy to maintain thanks to its self-lubricating design which also reduces wear and tear, extending its operational life. Its variable tension is can be adjusted using a digitally controlled dial. Tension capability is up to 80kgf.

This machine comes with a 12 month warranty.

| Technical details | |

|---|---|

| Width | 1254 mm |

| Depth | 609 mm |

| Height | 1403 - 1508 mm |

| Weight | 146 kg |

| Table height | 820, 850, 880, 910, 940 mm |

| Tension capability | 80kgf |

| Minimum package size | W 80 x H 30 mm |

| Maximum package size | W 620 x H 480 mm |

| Strapping Type | Polypropylene, ID 200 x OD 450 x W 200 mm |

| Strap width | 5, 6, 9, 12, 15.5 mm |

| Power supply | 100 – 240V Single phase 50/60Hz 0.9KVA |

How to use our tabletop paper or film semi auto strapping machine

Our low cost, general purpose semi-automatic strapping machine can be used with a range of goods as and when needed. Start by turning the machine on, and then use the feed and tension buttons to customise how long you would like the strapping to be and how tight. Place items onto the machine and feed through the first piece of strapping. Wrap round the products, feeding the strapping back into the machine. This will tension and cut the strapping effortlessly. This machine should be used with Polypropylene strapping.

How to use our tabletop paper or film semi auto strapping machine

Our high speed table top strapping machine can apply either paper or film around goods. The machine is ideal for small to medium goods. Simply insert and press button to apply strapping, or use a foot pedal for efficiency.