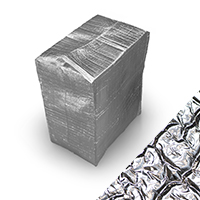

Pallet wrap

At Kite Packaging, we stock a wide range of hand and machine pallet wrap, with options for white, black, red and blue film and even custom film printed with your logo.

Choosing the right pallet wrap for your business can be confusing. Whether you're looking to use your pallet wrap for storage or shipping, our team of packaging advisors can guide you through the process over the phone.

Simply call us on 02476 420065 and a member of our team will be happy to discuss the packaging solutions best for your business and pallet contents.

Pallet Wrap Film

Our pallet wrap rolls come in 400mm and 500mm widths and range from 12 to 34 microns, ensuring the right level of strength and flexibility for your packaging requirements. Clear and black mini stretch films in a 100mm width and 15 microns also available.

For the specifications of each type of pallet wrap, simply click the ‘More Info’ icon in the product tables. With the option for next day delivery, your pallet wrap can with you and ready for use in 24 hours.

Book Your Free Pallet Wrap Audit

Many businesses overlook pallet wrapping, but using the right wrap type and technique for your pallet loads is essential for stability, cost savings, and efficiency. Our free pallet wrap audit assesses your wrapping process, film usage, and load retention, helping you find the perfect solution to reduce waste, improve safety, and save money.

Book your free audit today – call 02476 420065 to see if you qualify and get started.

Different Types of Pallet Wrap Films

We have high quality pallet wrap solutions for every business need, from cast films to puncture-resistant blown pallet wrap. This includes a range of colours along with environmentally friendly options like ventilated pallet wrap, which is 100% recyclable.

Pallet wrap is either applied by hand/with a dispenser or with pallet wrapping machines:

Hand Stretch Wrap

Hand stretch wrap use has risen recently with the availability of innovative dispensers which make the job easier. Great for small to medium businesses where a low number of pallets wrapped are daily, or where workers wrap pallets in multiple locations on site.

The types of hand stretch wrap are:

- Flush Core – Designed for use with dispensers, offering better control and ease of handling.

- Extended Core – Features a built-in handle for comfortable manual wrapping, making it ideal for hand application.

- Coreless Film – A more eco-friendly option with no cardboard core, reducing waste. Best used with our coreless dispenser.

Machine Stretch Wrap

Machine stretch wrap is designed for users who operate pallet wrap machines. Our manufacturers use high performance, high yield materials so you can confidently stabilise pallets.

Pallet Wrapping Machines

Our semi-automatic pallet wrapping machines wrap pallets in seconds and are ideal for medium to high volume users. There are a variety of options available for heavy duty use for a cost-effective solution that also reduces film use.

Robot pallet wrappers are ideal for businesses where pallet wrapping occurs in various locations on site, great for instances where pallet sizes are irregular or too large for a machine turntable.

Although not a machine, our 5 x 5 hand pallet wrap dispenser provides machine technology and efficiency in the hand. It pre stretches film and reduces plastic consumption by up to 30%.

Frequently Asked Questions

We've answered some common questions on pallet wrap below. For more guidance, see our pallet stretch film FAQs and our blog on the difference between blown and cast pallet wrap.

What is the Difference Between Cling Wrap and Pallet Wrap?

Cling wrap is designed for sealing food containers and preserving freshness, while pallet wrap is used for securing and stabilising loads during transport.

Can I Use Pallet Wrap for Food?

Yes, pallet wrap can be used for food, but only specific types like ventilation pallet wrap, which allow airflow to prevent spoilage.

.jpg)